In House, 3D Rapid Prototype

Jul 16th 2020

Here at Killerglass were proud to do as much "in house" all under one roof as possible.

Besides making the glass products we also make our LED mounts, tooling for our machines and make our own machines.

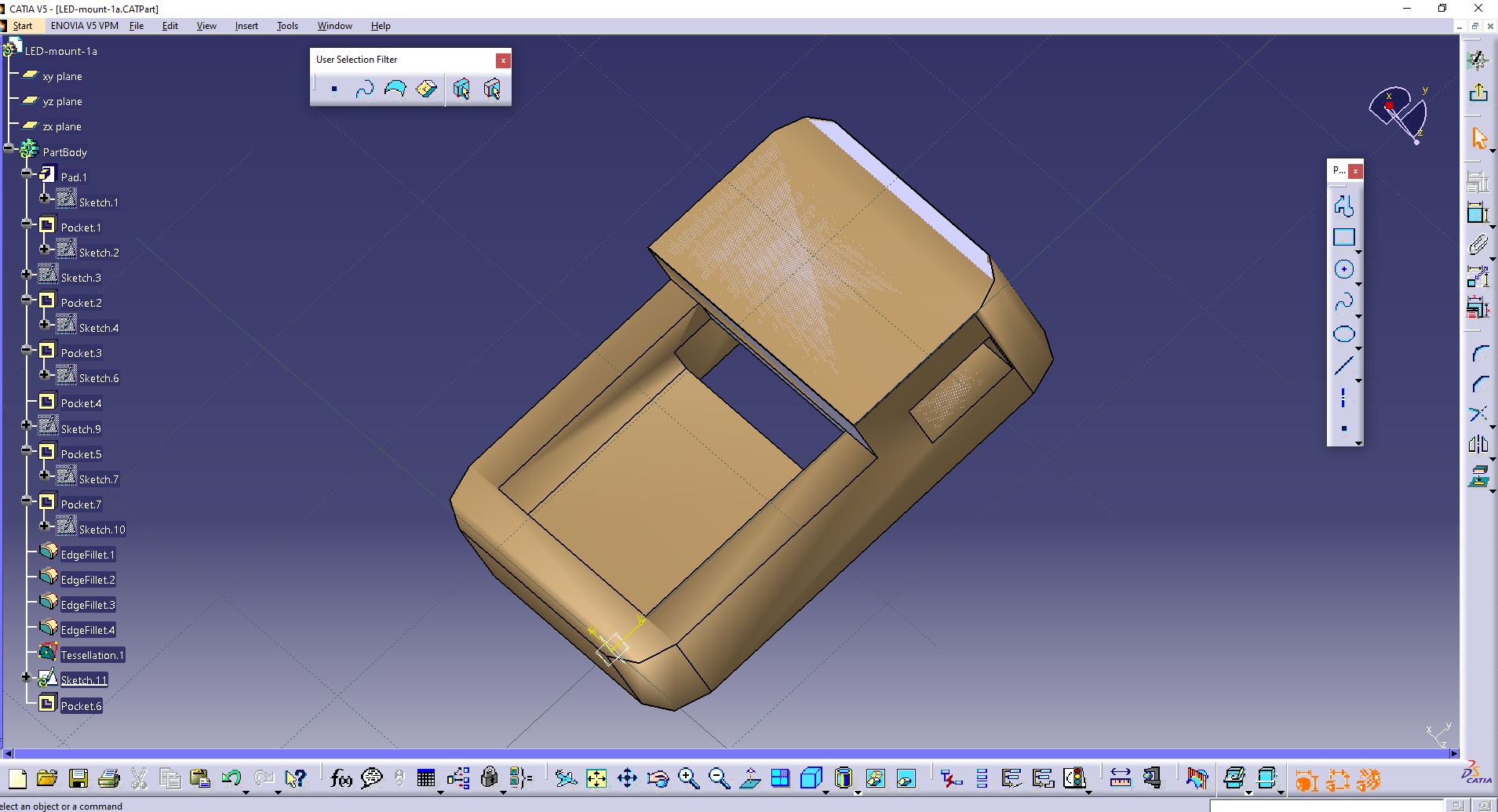

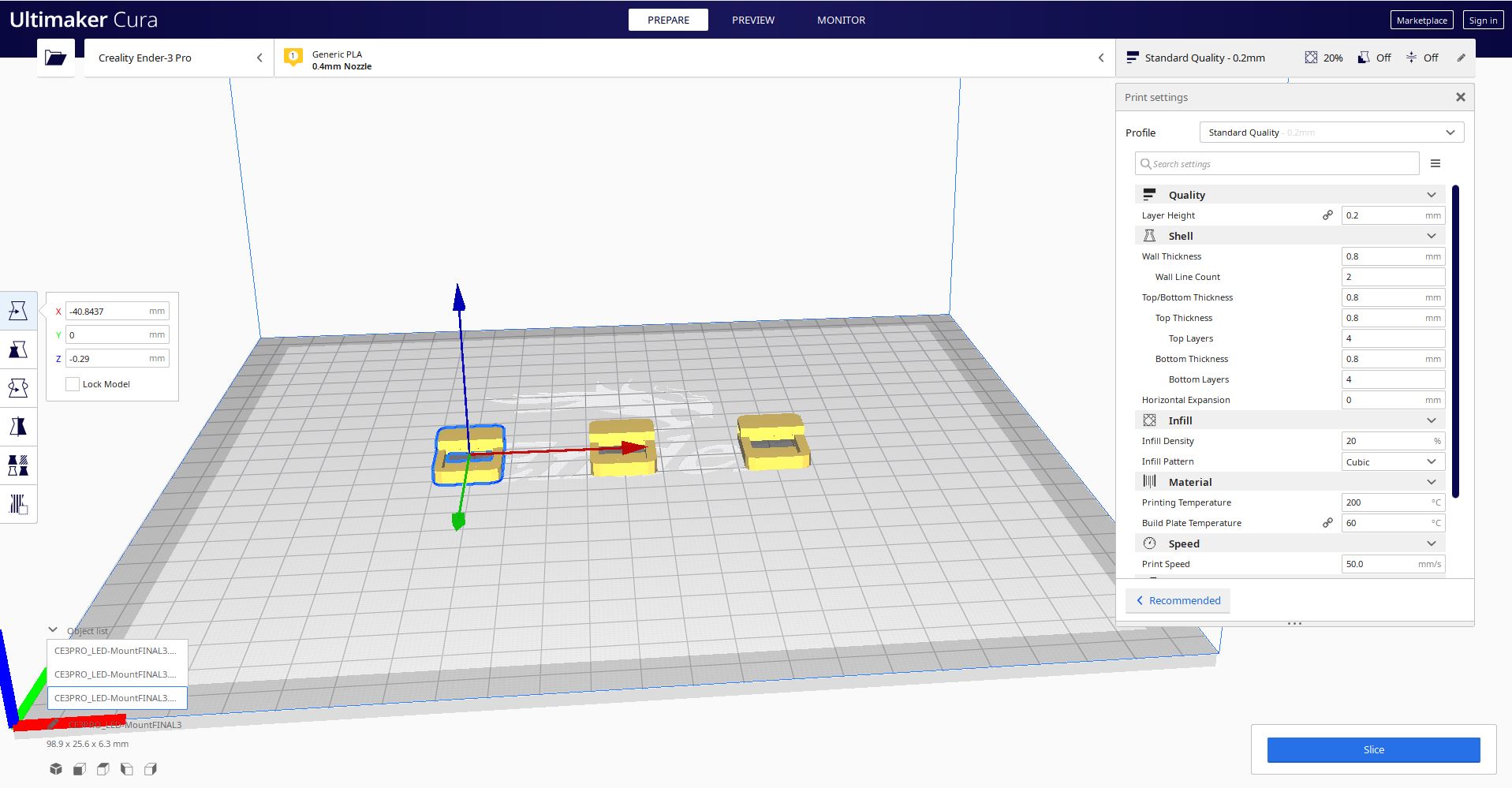

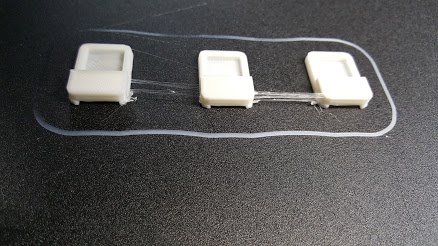

Here is the process for those simple little mounts that hold the LED on the tube.

They are designed in a CAD program > exports to a rapid prototype program to make the final "g-code" > sent to the 3D printer to make the model. This model is test fitted then put into production.

Here is a quick video and few shots of the process.